Five In-Demand Semiconductor Jobs: What Skills are Needed?

17 Oct, 202410 mins

Hiring for in demand semiconductor jobs is tough right now, and Acceler8 Talent helps you focus on the five roles that matter most for delivery, plus the skills that signal who will actually move yield, quality, and time to market.

Key Takeaways:

- The most in demand semiconductor jobs are process, design, test, equipment, and materials, covering the full chip life cycle.

- Strong candidates mix solid academic foundations with hands on cleanroom, CAD, test, or lab experience.

- Soft skills like communication, problem solving, and teamwork often decide who succeeds in high pressure fab and design environments.

- A clear hiring brief, fast feedback, and structured interviews will help you secure top talent before competitors do.

- Partnering with a specialist like Acceler8 Talent gives you access to passive candidates and saves you time on shortlisting.

The market for in demand semiconductor jobs

If you feel like every good semiconductor engineer is already under offer, you are not alone. Many hiring managers are trying to fill the same roles with the same small pool of experienced people.

Why is it so hard to hire semiconductor engineers right now?

The reason it is so hard to hire semiconductor engineers right now is that demand for chips is rising faster than the supply of specialist talent.

AI hardware, electric vehicles, 5G, and industrial automation all need advanced semiconductors, and each of these areas is growing. At the same time, many engineers are drawn into software or big tech, so you are fighting for attention before you even talk about salary.

Which sectors are driving demand for semiconductor jobs?

The sectors that are driving demand for semiconductor jobs most strongly are automotive, AI and data centers, telecoms, consumer electronics, and industrial equipment.

Automotive players want power devices and sensors that are safe and reliable. Cloud and AI providers want high performance compute and memory. Telecoms needs RF and mixed signal devices. Each sector leans on the same core skills, so experienced engineers rarely stay on the market for long.

The five in demand semiconductor roles you should prioritise

You do not need to hire every job title under the sun to support your roadmap. In practice, five semiconductor roles come up again and again because they control yield, performance, and delivery.

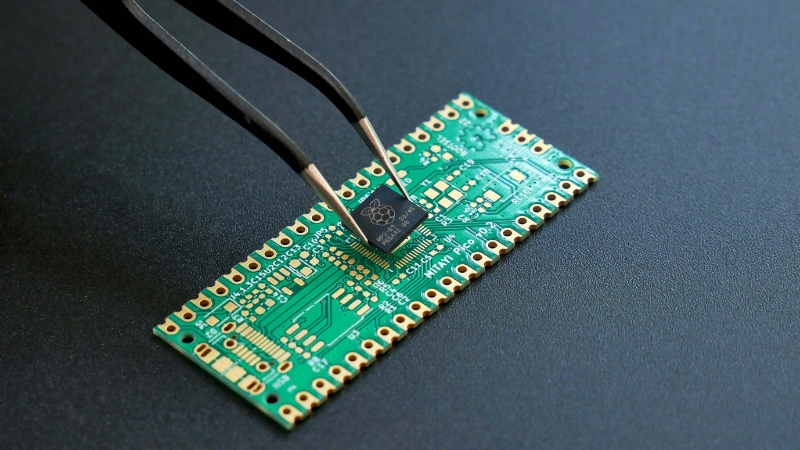

What does a semiconductor process engineer do?

A semiconductor process engineer is responsible for building and refining the wafer processes that turn raw materials into working devices.

They work across steps like lithography, etch, deposition, and CMP, and spend a lot of time in the fab, close to the tools.

Typical profile and skills:

- Degree in physics, chemistry, materials science, or electrical engineering.

- Experience in a cleanroom, with exposure to one or more process modules.

- Strong data skills, including SPC, DOE, and root cause analysis.

- Clear communication with operators, equipment engineers, and yield teams.

A common mistake we see is hiring for process knowledge alone and ignoring the need to explain issues clearly across shifts and sites.

What skills does a semiconductor design engineer need?

A semiconductor design engineer needs the skills to turn product requirements into manufacturable integrated circuits.

They define architectures, create schematics, write HDL, and work with layout and verification teams to reach tape out.

Key qualities to look for:

- Degree in electronics or electrical engineering.

- Proficiency with CAD and EDA tools for schematic, layout, and simulation.

- Strong skills in Verilog or VHDL, plus Python or C for scripting and checks.

- Awareness of design for test and design for manufacturability.

Here is a quick insider tip: the best design engineers show evidence of silicon debug and bring up, not just clean project lists. That is where their problem solving really shows.

What does a semiconductor test engineer focus on?

A semiconductor test engineer focuses on proving that every device works as intended and survives the stresses of real use.

They write test programs, run wafer and final test, and work closely with design and product teams on bring up and failure analysis.

Core skills and experience:

- Degree in electrical, electronics, or computer engineering.

- Experience with automated test equipment and wafer probers.

- Strong scripting skills in Python, C or C plus plus, and tools like LabVIEW.

- Knowledge of reliability tests such as HTOL, ESD, and temperature cycling.

The usual difference between average and great test engineers is their ability to interpret data and tell a clear story back to design and process teams.

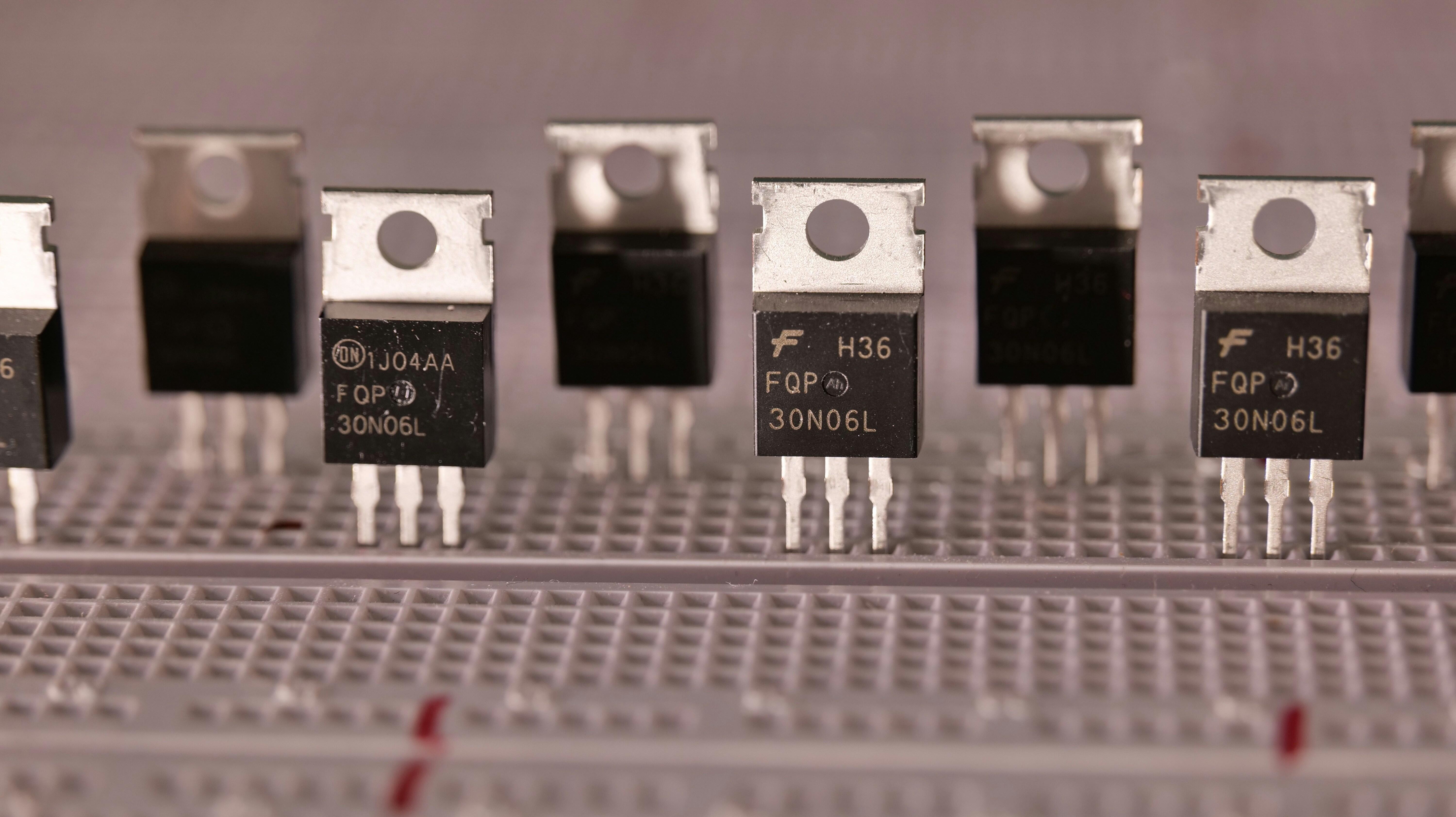

What is the role of a semiconductor equipment engineer?

The role of a semiconductor equipment engineer is to keep fab tools running safely and efficiently so production targets are met.

They own uptime and performance for tools such as steppers, etchers, deposition systems, and metrology equipment.

What you should expect:

- Degree in mechanical, electrical, or mechatronics engineering.

- Hands on experience with planned and reactive maintenance on complex tools.

- Understanding of uptime, mean time between failures, and overall equipment effectiveness.

- Calm communication during incidents and strong documentation habits.

A common mistake we see is hiring people who can swap parts but do not analyse trends. Data driven maintenance is where big gains in output come from.

What does a semiconductor materials scientist work on?

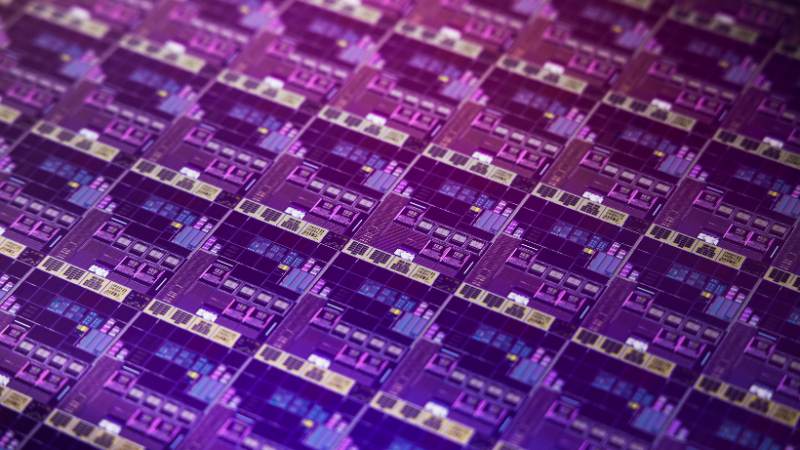

A semiconductor materials scientist works on the materials that give devices their performance, from silicon and silicon carbide to gallium nitride and new thin films.

They focus on how materials behave under stress, how they fail, and how to improve reliability and efficiency.

Ideal skills and profile:

- Degree, often postgraduate, in materials science, physics, or chemistry.

- Experience with lab techniques such as XRD, SEM, AFM, and spectroscopy.

- Modelling skills with tools like MATLAB, Python, or finite element software.

- Track record in collaboration with device, process, and reliability teams.

These candidates can be hard to find, and they often sit in central R and D teams that support several product lines at once.

How to hire for in demand semiconductor jobs

The outcome of this process is a faster, more confident hiring flow that secures better semiconductor talent before the competition.

Clarify the real business problem - Identify whether your main pain is yield, time to market, quality escapes, or tool uptime, then link it to the role that will have the most impact.

Write a skills first job brief - Focus your job description on six to eight clear skills, tools, and outcomes instead of a long wish list, so the right engineers self select in.

Benchmark salary and location realistically - Check current pay ranges and talent availability for each role and region, and decide in advance where you can flex on relocation or remote options.

Screen for evidence, not buzzwords - Ask candidates for specific examples of yield gains, downtime reductions, or successful tape outs, rather than just tool and language lists.

Use structured technical interviews - Build a repeatable set of questions and simple tasks so every candidate is judged on the same criteria and bias is reduced.

Tighten your feedback loop - Set internal deadlines for CV review and interview feedback, because strong semiconductor candidates often juggle several processes.

Partner with a specialist recruiter - Work with a specialist like Acceler8 Talent that speaks the same technical language as your candidates and already has access to passive talent.

Semiconductor hiring FAQs

Q: What are the most in demand semiconductor jobs right now?

A: The most in demand semiconductor jobs right now are process engineers, design engineers, test engineers, equipment engineers, and materials scientists, because these roles control yield, performance, quality, and uptime across the full chip life cycle.

Q: What degree is best for a career in semiconductor engineering?

A: The degree that is best for a career in semiconductor engineering is usually electrical or electronics engineering for design and test roles, and physics, chemistry, or materials science for process and materials roles, since these subjects build strong foundations in device physics and circuit behaviour.

Q: How long does it usually take to hire a semiconductor engineer?

A: The time it usually takes to hire a semiconductor engineer is often between four and twelve weeks, depending on seniority, notice periods, and how quickly your team can move candidates through interviews and decisions.

Q: What skills should I prioritise for semiconductor test roles?

A: The skills you should prioritise for semiconductor test roles include automated test equipment experience, scripting skills in Python or C plus plus, understanding of reliability testing, and the ability to read data and share clear feedback with design and process teams.

Q: How can I make my semiconductor job offer more attractive to candidates?

A: The way you can make your semiconductor job offer more attractive is by combining competitive pay with clear progression, flexible working where possible, and direct involvement in interesting projects, since experienced engineers value impact and learning as much as basic salary.

About the author

This article was created by a content specialist who works closely with semiconductor recruiters and hiring managers. They draw on live search data, real interview feedback, and current hiring projects across Europe and North America to give practical guidance to busy leaders who need to secure scarce technical talent.

Partner with Acceler8 Talent for specialist semiconductor hiring

If you need to fill critical roles in process, design, test, equipment, or materials, you do not have to manage it alone. A specialist partner can help you refine the brief, benchmark salaries, and reach candidates you would not see through adverts alone.

Contact Acceler8 Talent today to speak with a consultant, share your hiring plans, and get a clear view of the semiconductor talent market in your niche.