Building your Team for the 4 Stages of Semiconductor Development

23 Oct, 202411 mins

Semiconductor development can be a complex process that requires critical stages to be completed. From research and development, design and prototyping, manufacturing, and testing and validation, each phase of the process is paramount. These stages could not be finished without the input and efforts of an expert team.

With that said, read our guide to find out how you can build a team that ensures your business can maximize the 4 stages of semiconductor development.

Stage 1: Research and Development

Research and development form the basis of most scientific projects and tech-related endeavors; semiconductor development is no exception. R&D presents the opportunity to highlight market needs, which leads to transforming concepts into tangible technologies. Innovation is integral for the continued progression of semiconductor devices. Donald Trump’s planned tariffs demonstrate the demand.

He’s stated that he will impose tariffs on foreign-made chips, which would be a welcome policy for US semiconductor companies. America’s share of overall chip production has declined from 37% in 1990 to just 10% today. Trump’s tariffs aim to change with:

- A 60% tariff on goods coming from China.

- A 20% tariff on all imports - including semiconductor chips.

According to Patrick Moorhead, founder, CEO, and Chief Analyst at Moor Insights and Strategy, the proposed tariffs could increase semiconductor jobs related to chip manufacturing. Jeff Ferry, chief economist at Coalition for a Prosperous America, agrees. He believes the tariffs could create ten additional factories and around 100,000 jobs for US chip manufacturers.

In addition to the government support, R&D for semiconductor development is receiving capital from a string of U.S. semiconductor companies in 2024:

- Intel Corporation: $16.52 billion

- QUALCOMM Incorporated: $8.86 billion

- NVIDIA Corporation: $7.81 billion

- Advanced Micro Devices Incorporated: $5.73 billion

It’s a hugely lucrative market, substantiated by revenues forecast to reach around $83.60 billion in 2024. Furthermore, revenue is predicted to show an annual growth rate (CAGR 2024-2029) of 9.40%, leading to a total market volume of $131.00 billion by 2029. In a global context, the majority of revenue will be driven by China. However, with Donald Trump’s tariffs, could this trend change during his presidency?

How to Build an R&D Team for Semiconductor Development

It’s evident that financially supporting R&D for semiconductor development is of interest to governments and companies alike. Which roles are tasked with utilizing this enormous investment and ensuring semiconductor devices become more sophisticated and efficient?

Research and Development Engineers

At the forefront of driving semiconductor development are R&D Engineers. Their primary role is to create pioneering solutions for the industry. Here’s an overview of what they’ll provide for your team:

- Meticulous research covering emerging materials, technologies, and design approaches.

- Design and develop the latest semiconductor devices.

- Leveraging semiconductor equipment to conduct comprehensive testing and verification.

Process Engineers

Process Engineers focus on optimizing the semiconductor manufacturing process and are pivotal for your team. Here’s why:

- They design and develop the manufacturing process and work on areas including photolithography, ion implantation, and wet etching.

- Process Engineers will integrate new processes to consistently elevate procedures.

- Quality is assured as they’ll monitor and control the process to ensure optimal output and an improved yield.

Materials Scientists

To design semiconductor devices with maximum efficacy, your R&D team will require materials scientists because they:

- Work on developing new semiconductor materials and advancing existing ones for improved performance.

- Hone their fabrication techniques (such as Extreme Ultraviolet Lithography) to create smaller semiconductor devices without sacrificing power.

- Thoroughly study the structure and properties of semiconductor materials using tools like optical and electron microscopy, X-ray diffraction, and spectroscopy.

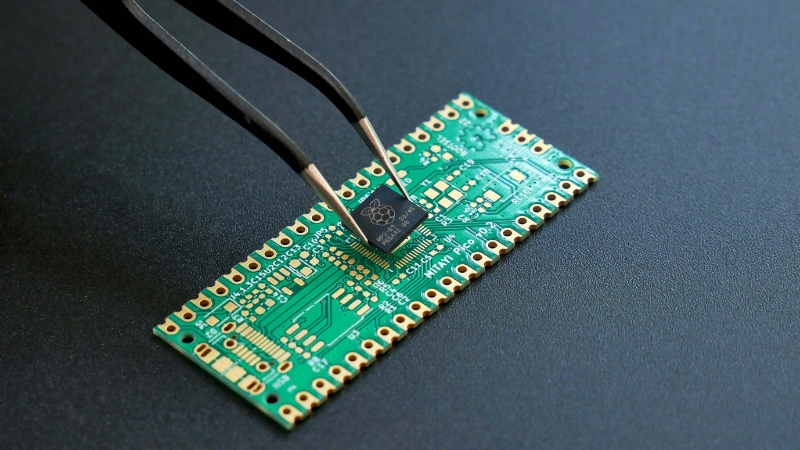

Stage 2. Design and Prototyping

Following R&D, the semiconductor development process progresses by implementing findings before full-scale production. This is known as the design and prototyping phase. This phase is particularly important as it allows semiconductor manufacturers to detect and rectify flaws and ensure a high-quality product is put on the market.

On that note, the semiconductor industry is an extremely competitive market. Semiconductor devices must be promptly produced and ready for market. Prototyping allows for:

- More efficient product development cycles.

- Earlier development of software.

- Customer feedback that can be implemented.

As we know from discussing the R&D stage, huge sums of money are involved in semiconductor development investment. However, if the correct procedure isn’t adhered to during prototyping, semiconductor companies could face substantial financial setbacks. Here’s how:

- Mitigates the risk of production errors.

- Reduced need for expensive reworks.

Design and prototyping are paramount to ensure the consistent progression of chip designs. Sophisticated and detailed chips can be designed by utilizing computer-aided design (CAD) tools, let’s explore how:

Design Entry and Simulation

During semiconductor development, CAD tools allow engineers to use various methods to create initial designs, for example:

- Schematic Capture: Engineers can sketch detailed circuit diagrams using graphical interfaces.

- Hardware Description Languages (HDL): This tech lets Design Engineers describe circuit behavior.

- Simulation: CAD tools can verify circuit behavior before implementation, including digital simulation for logic verification and timing analysis for proper signal propagation.

Synthesis and Optimization

Where digital designs are concerned, CAD tools are used to offer engineers the following:

- Logic Synthesis: This converts HDL descriptions into gate-level representations.

- Physical Synthesis: Fuses logical and physical design to maximize performance, power, and area.

Layout and Physical Design

CAD tools enable Design Engineers to create a physical representation of the chip with the following methods:

- Place and Route: Automates the positions of logic gates and creates interconnections in accordance with design rules.

- Custom Layout: Tools such as Cadence Virtuoso allow manual layout creation for analog and specialized circuits.

- Design Rule Checking (DRC): Ensures the layout meets semiconductor manufacturing processes.

- Layout v Schematic (LVS): The verification of a physical layout matching the intended circuit schematic.

Assembling Your Design Team

When building a design team for effective semiconductor development, individuals must be equipped with skills in digital and analog circuit design, layout, and verification.

Analog Design Engineers

These professionals are responsible for developing integrated circuits (ICs) essential for semiconductor development. Analog Design Engineers aren’t just important for your team; they’re integral to the industry:

- Analog circuits are needed for interfacing with the physical world, turning signals to digital form and vice versa.

- Several industries, such as automotive, telecommunications, and medical devices, rely on analog ICs.

- The analog IC market is forecast to experience growth of around $102 billion by 2028.

Physical Design Engineers

This aspect of semiconductor development centers around transforming logical circuit designs into physical layouts that are manufacturable. What will they bring to your team?

- A mastery of semiconductor physics and manufacturing processes.

- Adept with scripting languages like Tcl and Python.

- Comfortable with DRC and LVS tools.

Verification Engineers

Verification Engineers design and execute tests to ensure intricate hardware systems perform optimally and meet necessary specifications. What makes them so crucial for semiconductor development?

- With semiconductor devices becoming more complex, formal verification techniques are vital to detect possible defects and ensure specifications are met.

- Verification ensures compliance with industry standards. For example, ISO 26262 is for automotive, and DO-254 is for avionics.

- Verification Engineers ensure that designs perform as they should before they’re produced.

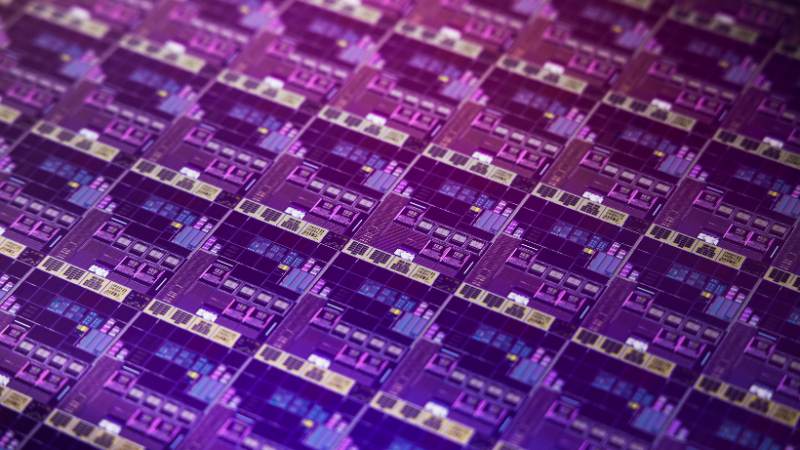

Stage 3. Manufacturing

Last year, the semiconductor market had an estimated value of around $544.78 billion. By 2033, it’s believed that sum could rise to an astronomical $1,137.57 billion and have a CAGR growth of 7.64% from 2024 to 2033. As 2024 draws to a close, it was forecast that U.S. tech companies would be responsible for America’s growth of 25.1%.

Projected growth highlights the need for semiconductor devices now and in the future. For semiconductor development to meet market demands, manufacturing processes must be optimal. This can be done through:

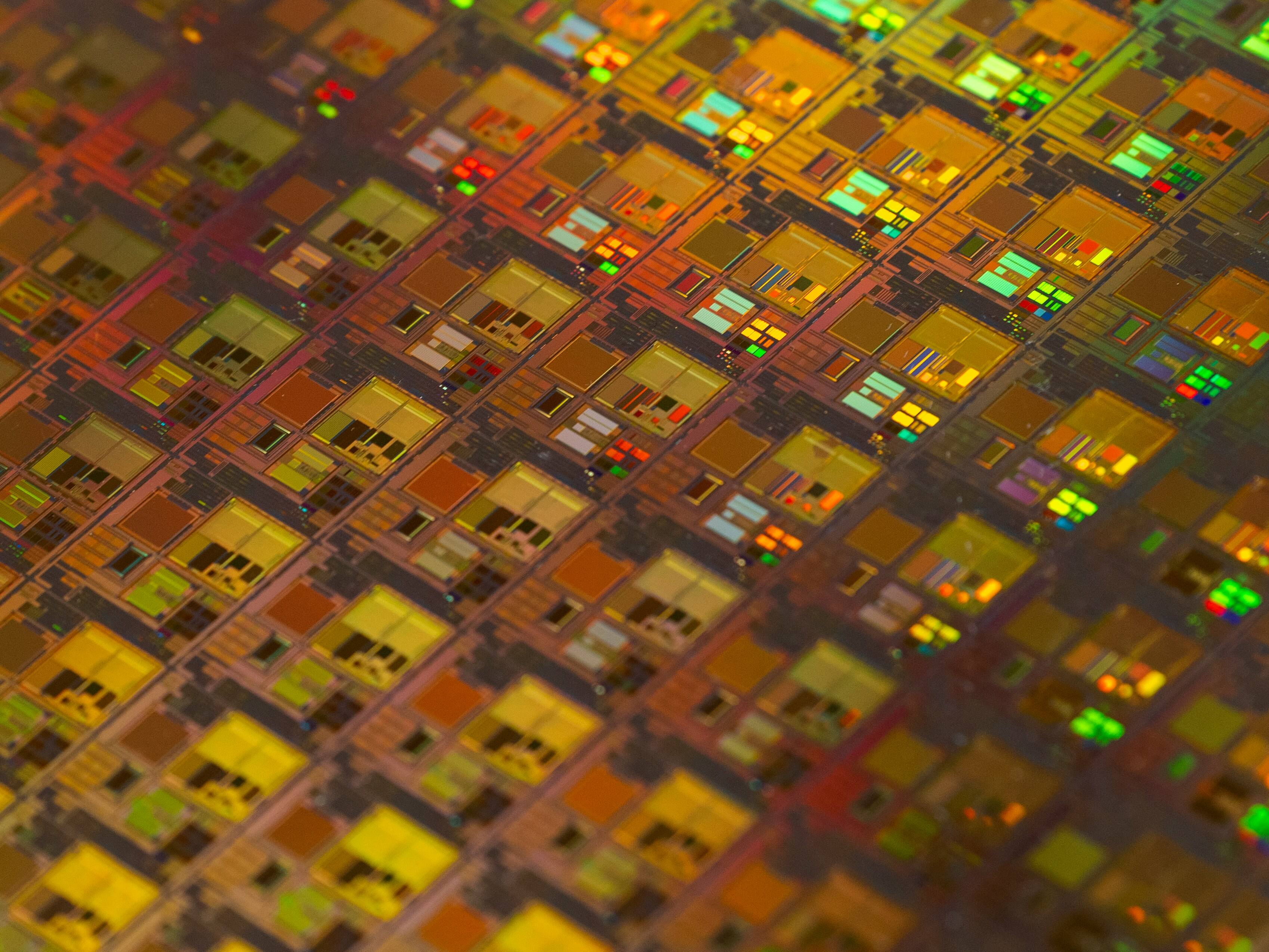

Advanced Lithography Techniques

Extreme Ultraviolet (EUV) lithography technology allows semiconductor devices to have precise patterning at miniature scales. High-NA EUV, which is an updated version with bigger lenses, will be capable of resolutions below 2nm.

New Transistor Architectures

Traditional planar transistors are being replaced by cutting-edge 3D architectures, such as:

- FinFETs: This tech has a fin-like structure to control the flow of current, while 3D transistors use multiple layers stacked on top of each other, allowing for elevated scaling without the restrictions from planar transistors.

- Gate-All-Around (GAA): Anticipated to be necessary for 2nm nodes onwards and will offer better performance and short channel control.

- Worksheet: An architecture that extends GAA concepts to 1nm.

- Complementary FET (CFET): A vertical transistor that has the potential to allow for further scaling.

Materials Scientists are exploring ways to overcome the restrictions associated with using silicon, for example:

- Tungsten disulfide (WS2) or molybdenum disulfide (MoS2) are ultra-thin 2D materials ideal for atomic-scale transistor channels.

- High-k dielectrics that mitigate short-channel effects and improve transistor performance.

Making Your Manufacturing Team

Your manufacturing team should have expertise in process engineering, equipment maintenance, and quality control. These three elements are key for smooth semiconductor development, and the following roles are equally key:

Process Engineers

Process Engineers concentrate on the optimization of semiconductor manufacturing processes. When part of your team, they’re responsible for:

Design and Optimization

There are various steps for semiconductor fabrication that will be optimized by Process Engineers, including:

- Photolithography: Streamlining photolithographic processes for accurate patterns on silicon wafers.

- Etching: Improving etching techniques to remove certain materials from the wafer surface.

- Deposition: Refining methods when depositing thin films of materials onto the wafer.

Process Control and Monitoring

It’s vital that Process Engineers maintain consistent and high-quality production of semiconductor devices. They’ll do this through:

- Incorporating statistical process control (SPC) methods to audit process stability.

- Using data from in-line metrology tools to detect and rectify process variations.

Equipment Engineers

These experts maintain and optimize complex semiconductor manufacturing equipment and have the following areas of focus:

- Wafer Processing Equipment: Designing and optimizing tools for etching, deposition, and lithography processes.

- Metrology and Inspection Tools: This semiconductor equipment is paramount for quality control.

- Vacuum Systems: Ensuring that vacuum-based equipment functions correctly.

Stage 4. Testing and Validation

Before semiconductor devices reach the market, they must be tested to ensure they meet specifications, and performance must be validated in real-world applications. Several tests can be utilized to gauge a chip’s performance and reliability. For example:

Functional Testing

This test is conducted to verify that the semiconductor chip functions within design specifications. This includes:

- Functional Verification: Ensuring all fundamental functions of the chip work.

- Boundary Scan Testing: Leveraging techniques like JTAG to check test input/output ports and verify circuit connections.

Parametric Testing

This type of testing is used to measure electrical characteristics of the semiconductor chip:

- DC Characteristics Tests: These measure current, voltage, and power consumption.

- AC Characteristics Tests: Utilized for frequency response, gain, phase, and more AC signal performance metrics.

Reliability Testing

Reliability tests assess a semiconductor chip’s performance in stressful conditions. Below are some examples:

- High-Temperature Tests: The chip is evaluated in extreme environmental conditions.

- Accelerated Aging Tests: Simulate long-term use through high temperatures.

- Temperature Cycling Tests: Thermal stability is tested through extreme temperature cycles.

- Electrostatic Discharge (ESD) Tests: Check the semiconductor’s durability to static electricity.

Creating Your Testing Team

A Test Development Engineer and Validation Engineer are critical for the aforementioned tests - and crucial for your team.

Test Development Engineer

A Test Development Engineer is necessary for your team to ensure the quality and reliability of semiconductor devices. Their responsibilities include:

- Test Program Development: Writing code in languages like C++ or Python to control automated test equipment (ATE) and evaluate semiconductor performance.

- Test Strategy Design: Design test strategies to ensure essential elements of a semiconductor device are properly scrutinized.

- Test Hardware Design: Design and develop the hardware required for testing - including test fixtures, probe cards, and interface boards.

- Data Analysis: Test results are thoroughly analyzed to uncover and correct anomalies.

Validation Engineer

A semiconductor device’s quality is dependent on rigorous testing. Therefore, a Validation Engineer is pivotal for your team. Here’s why:

- Design Validation: Validation Engineers will make sure that designs meet specifications before manufacturing.

- Pre-Silicon Validation: Before fabrication, sophisticated simulation and emulation tools are leveraged to assess its functionality.

- Post-Silicon Validation: To test physical chips and actual silicon, Validation Engineers perform bench validation utilizing oscilloscopes and logic analyzers to establish signal integrity.

Characterization Engineer

These engineers are also essential to building your semiconductor team for the following reasons:

- Device and Material Analysis: They will develop and incorporate test methods to scrutinize the optical components, electro-optic devices, and integrated circuits. They will also assess product designs via advanced bench testing equipment.

- Test Development and Execution: Characterization Engineers will create measurements and perform measurements as per characterization plans.

- Data Analysis and Reporting: Data will be studied so feedback can be provided to design teams.

Final Say: Building a Team for the 4 Stages of Semiconductor Development

Semiconductor development is driven by strong market demand, government support, and significant investment - particularly from U.S. semiconductor companies. There are four key stages to the process. Research and development, design and prototyping, manufacturing, and testing and validation. They all carry immense importance and require an experienced and skilled team.

Building an effective team for semiconductor development means that concepts become effective and reliable semiconductor devices. To achieve this, R&D Engineers, Materials Scientists, Process Engineers, and many more professionals contribute with their expertise.

Technological expectations will continue to increase, and semiconductor chips’ capabilities must consistently improve to meet the demands. Behind this demand is a need for a team of semiconductor experts. With knowledge of what’s required at each stage, companies can construct a team to create innovative chips and get a foothold in a competitive market.

Do You Need Cutting-Edge Talent?

At Acceler8 Talent, we’re passionate about embracing the speed of tech. Since 2019, we’ve been discovering the finest talent to help tech companies continue to be pioneers.

Discover how we can propel your business and ensure you maximize the 4 stages of semiconductor development. Visit our semiconductor and chip design page, or contact us and connect with a team member today.